Custom Inkjet Cartridge Filling System

Specifications

Customized machines for the inkjet cartridge industry

Besides the standard product line, Lobo Technik GmbH also offers design and product solutions according to the clients’ unique needs. We developed an extensive range of systems covering different areas, like quality control of empty cartridges, chip programming solutions, integrating the filling system via the internet into the manufacturer’s network, etc.

The following samples only show a small scope of Lobo Technik GmbH’s potentials. We like the challenge of creative work, and we are proud of the achievements of the past years. In this place, we are going to introduce you to a couple of examples for customized solutions.

High-performance ink filling system

Required features:

- Automatic filling, sealing, and final weight control of the cartridges

- Operation of the system by only one person

- The output of 15 cartridges per minutes

Chip programmer

Required features:

- Detecting the barcode, the mechanical key code, and the color of the ink-filled into the inserted cartridge

- Writing the required configuration onto the cartridge’s chip

- Saving the information into a database

Ink filling system integrated into the company’s network

Required features:

- Automatic filling, sealing, and final weight control of the cartridges

- Detecting the barcode, the mechanical key code of the inserted cartridges

- Writing the required configuration onto the cartridge’s chip

- Saving the information into a central database

- Operation of the system by only one person

- The output of 30000 cartridges per month in 2 shits

Bag filling system

Required features:

- Filling 4 different colors even at the same time

- Airtight sealing of the bag after the filling process by welding the filling connection

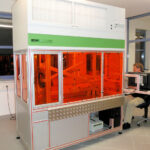

Cleanroom ink filling system

Required features:

- Automatic filling and sealing of the cartridges under cleanroom conditions

- Final weight control of the cartridges

- Writing the required configuration onto the cartridge’s chip

- Saving the information into a database

- Operation of the system by only one person