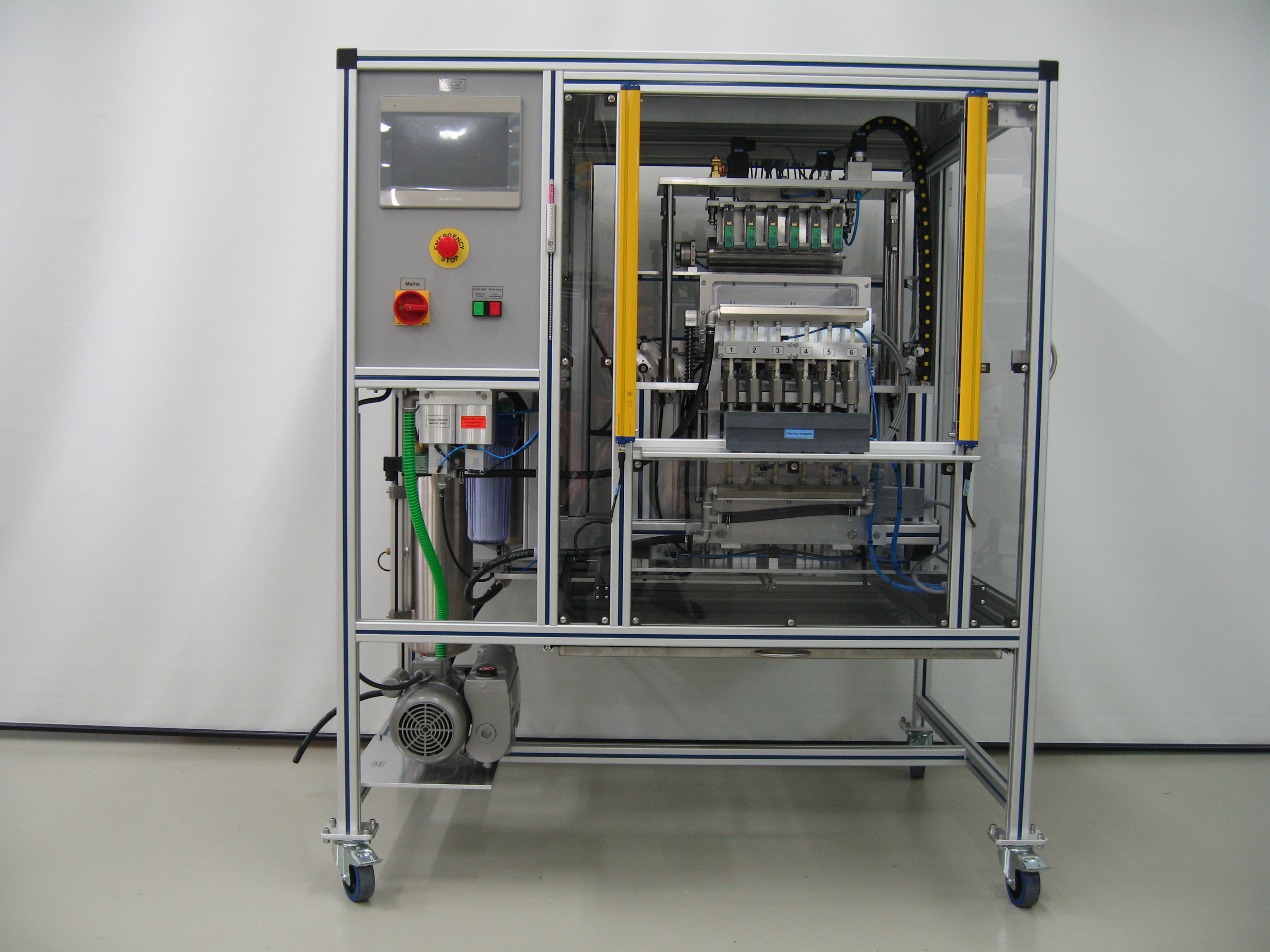

Autofill-6 HP45

Ink cartridges filling machine

The machine design enables the filling of six HP 45 type inkjet cartridges simultaneously. The advantages of this equipment are mainly suitable for OEM-s working with original cartridges. The maximum throughput of ink cartridges filling machine is around 180 cartridges per hour, largely depending on the ink quality.

Filling technology

All ink filling machines of Lobo Technik are using an exact syringe drive unit as a standard. This predosing enables to fill each cartridge with the same ink amount. It works perfectly with both solvent and water-based ink, but we do not recommend that our customers mix both types of ink in one machine. We use materials for all ink contacting parts that resist solvent-based inks in many alcohol variations. We can equip all ink contacting components of the machine on demand for FDA (food-grade) application and issue a certification. PLC controls the automatic filling process, provides maximum repeatability, and keeps the filling accuracy in the range of +/-0.2ml.

Machine performance videos are available on YouTube.

High vacuum filling

An essential attribute of the Autofill 6 is that the maximum force affecting the spring inside the cartridge is controllable. This method distinguishes the ink filling machine from other available solutions on the world market crucially because it is the only method capable of using maximum vacuum (99.8%) during the filling process without affecting the bag spring performance.

Intelligent software

The intelligent software of the machine offers many helping and controlling functions that make the operation safe and relatively easy.

To these functions belong for example:

- Many automatic self-test routines

- HMI panel

- Recording setups for different ink formulations

- Diagnostic capability by creating data log files

- Reminder function for periodical maintenance work

- Calculation and warning when the ink supply is running low

- Automatic check for the presence of sealing balls

- Automatic check whether the operator only empty cartridges inserted

And many others

Options

Some cartridge applications or ink formulations require the filling of degassed inks. Even though the ink cartridge filling machine uses a high vacuum, the proper ink preparation is important, especially with solvent inks. We offer for the ink degassing three different solutions.