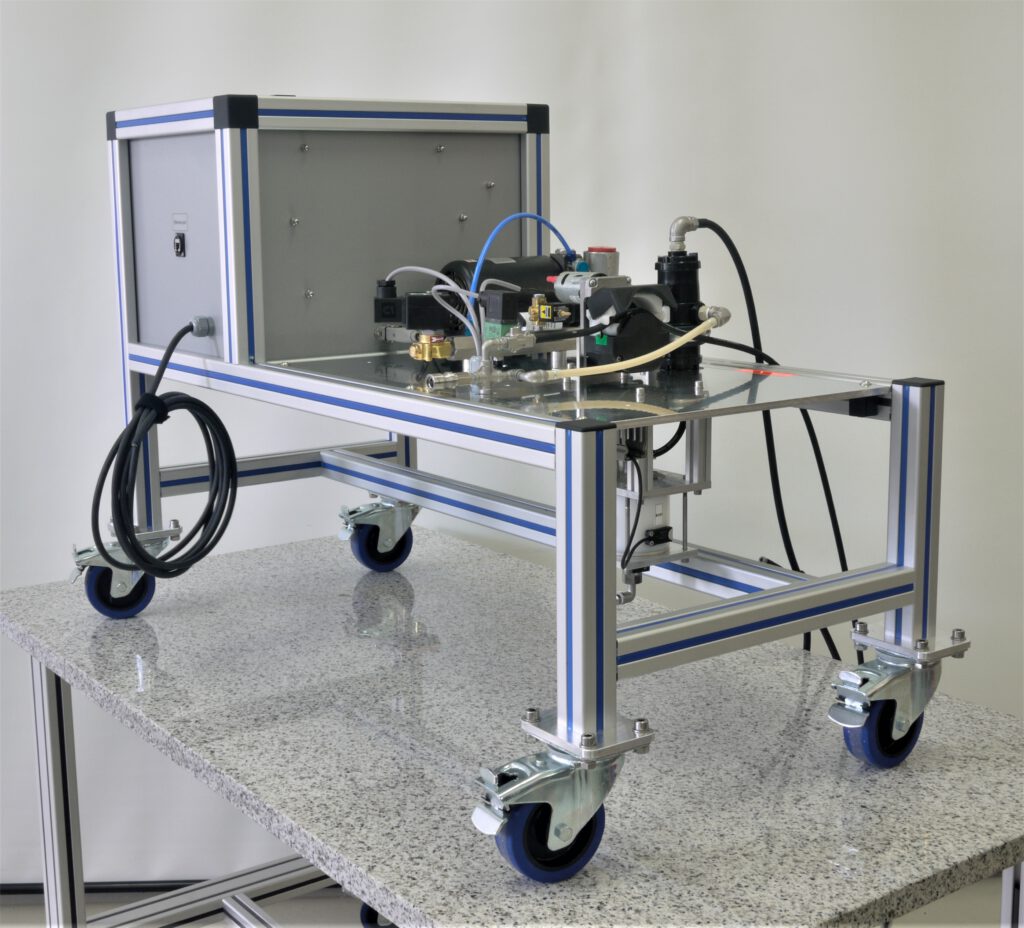

Standalone inline ink degasser – SID

Standalone ink degasser

We designed the standalone ink degasser for degassing the ink before filling it into a TIJ cartridge. The machine works with one or two inline degassing cartridges and is available for the Autofill-3 or Autofill-6 filling machines. The standalone ink degasser is also deployable with filling machines like FS6 for sponge-type cartridges. The machine is applicable as an independent unit or as the slave of the filling machine (the precondition is, the filling machine supports the slave function).

Solvent and water-based inks

The ink degassing machine is deployable for both solvent and water-based inks.

The limited cleaning ability of the degassing cartridges makes it necessary to either replace the degassing cartridges before changing the ink quality or to use different machines for the various inks.

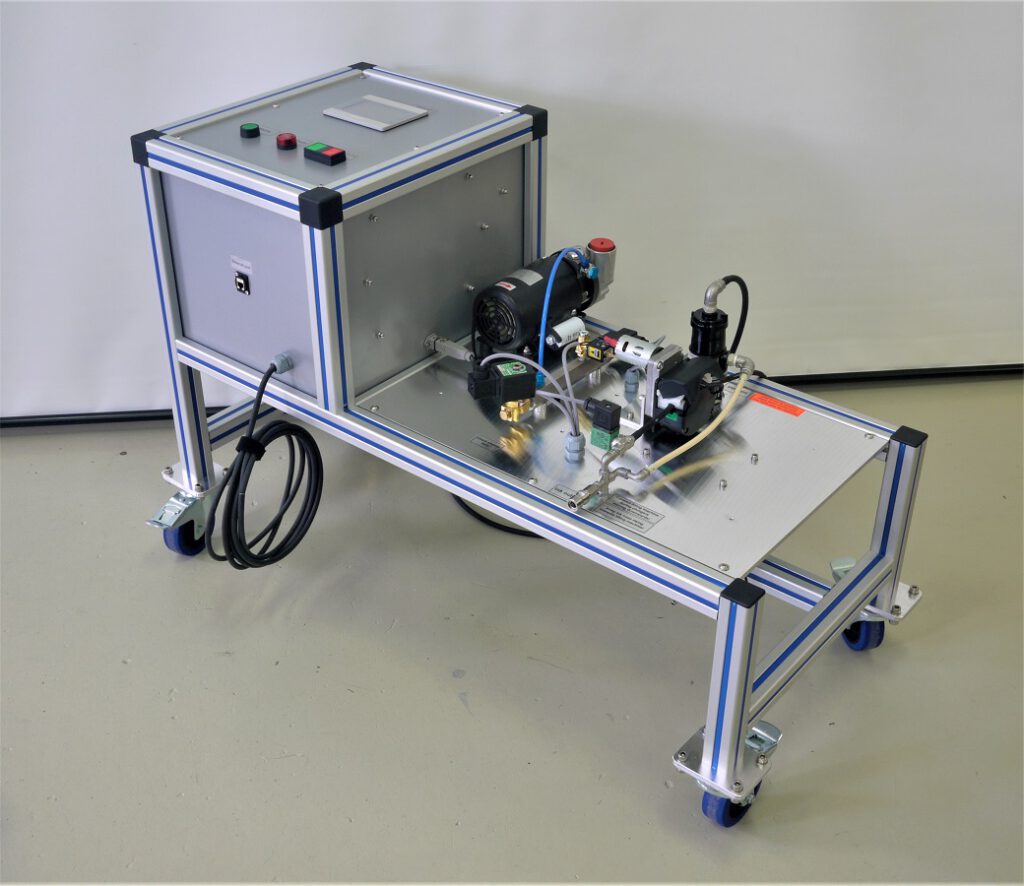

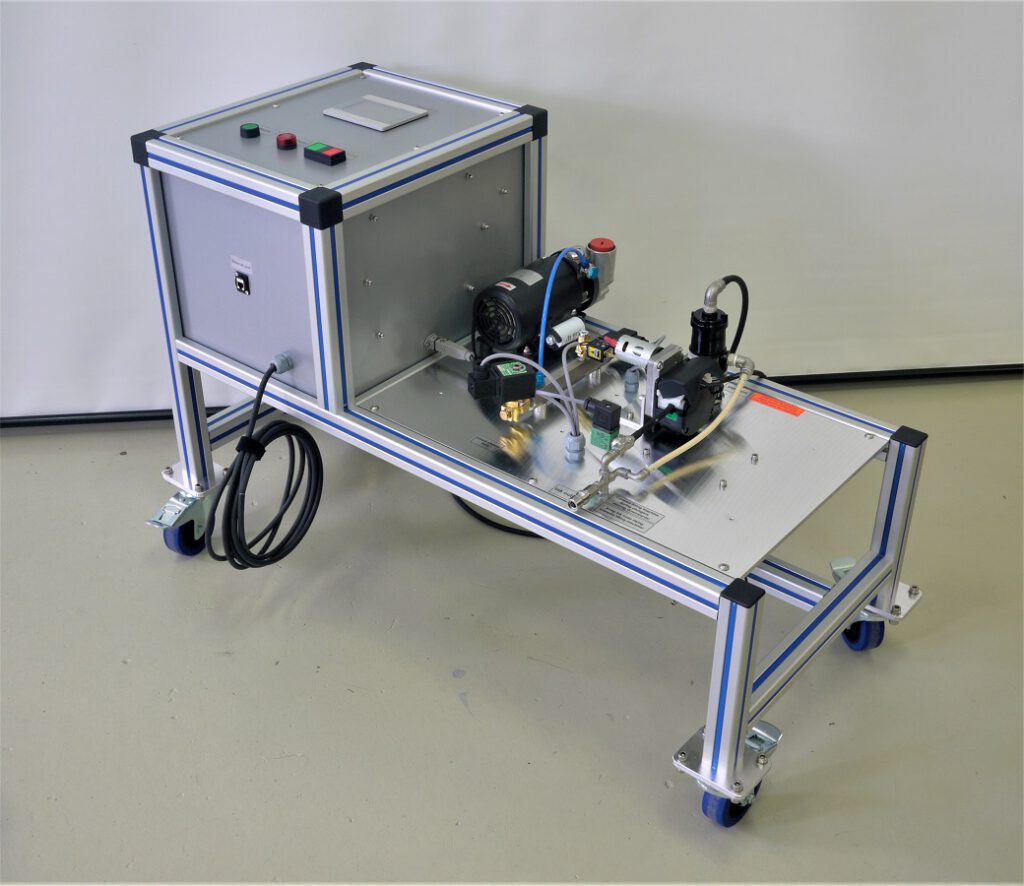

PLC-controlled process management

The communication with the machine takes place via an HMI-touch panel. A PLC controls the different functions, like the required pressure level of the system, and signalizes any malfunction if it occurs.

Advantages and disadvantages

- The standalone inline degassing machine is not bound to a specific filling machine and can be used with different filling machines as required.

- The handling is effortless and requires hardly any additional work or special qualifications.

- The application is particularly efficient when large batches are to fill with the same ink.

- The price is relatively high in comparison to the integrated inline degassing.